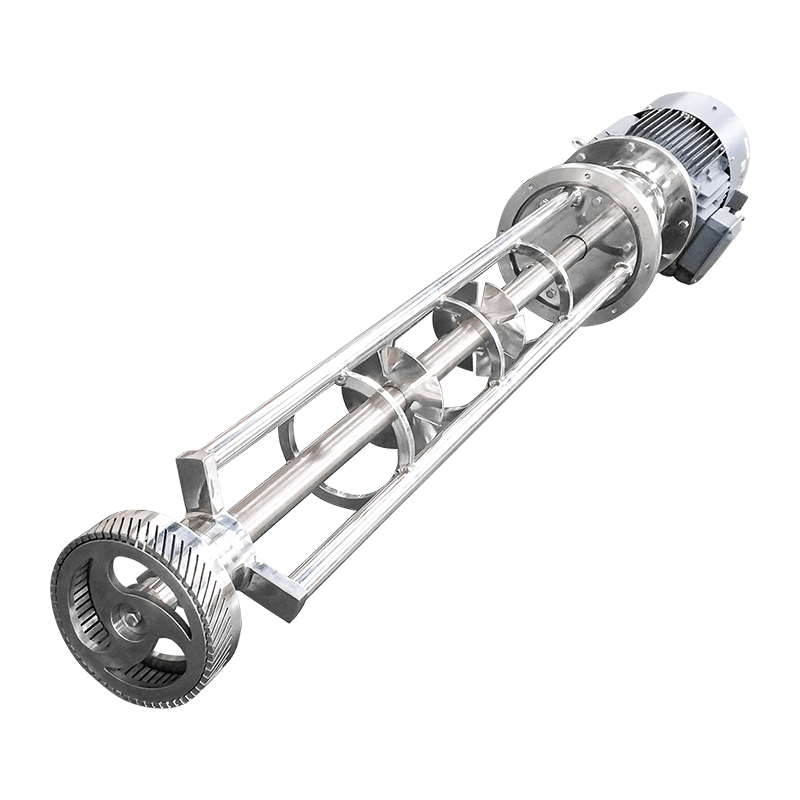

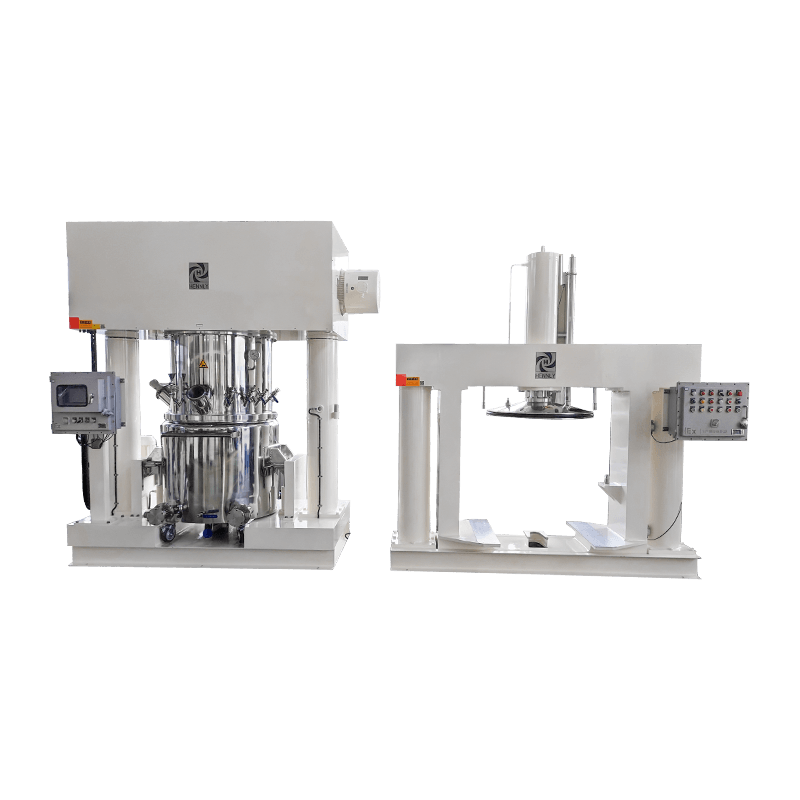

Features

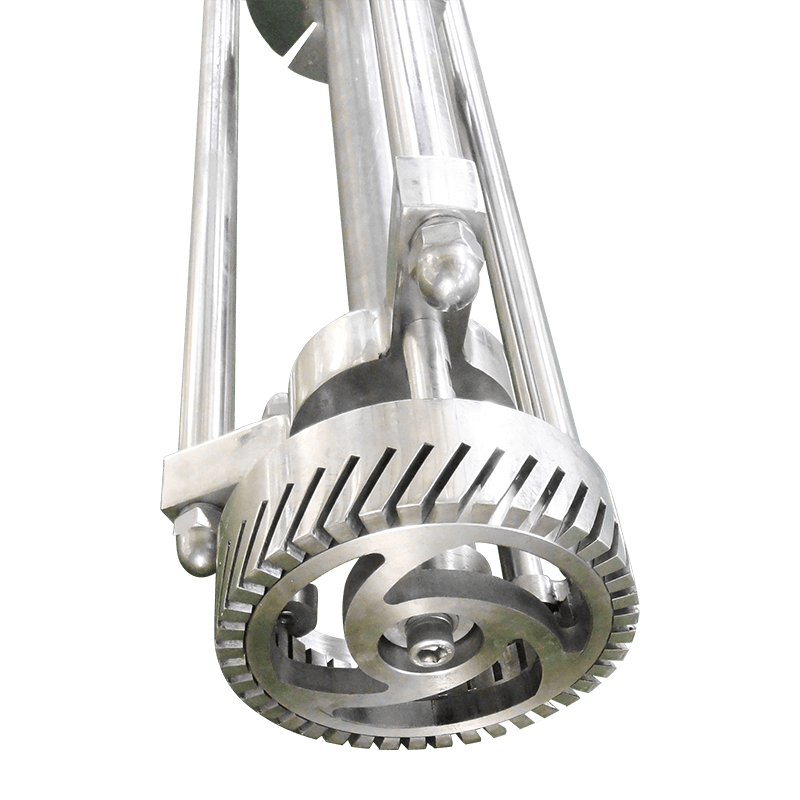

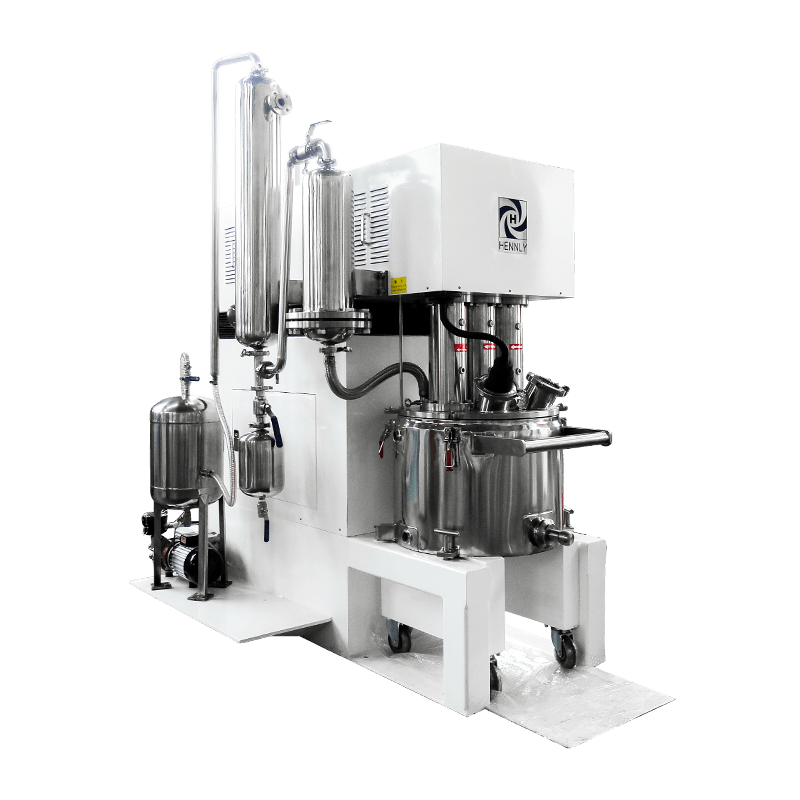

Highly efficient emulsification

Our gap emulsifier uses advanced emulsification technology to achieve high-quality emulsification results. Its unique gap design allows materials to be fully mixed in a very short time, improving production efficiency.

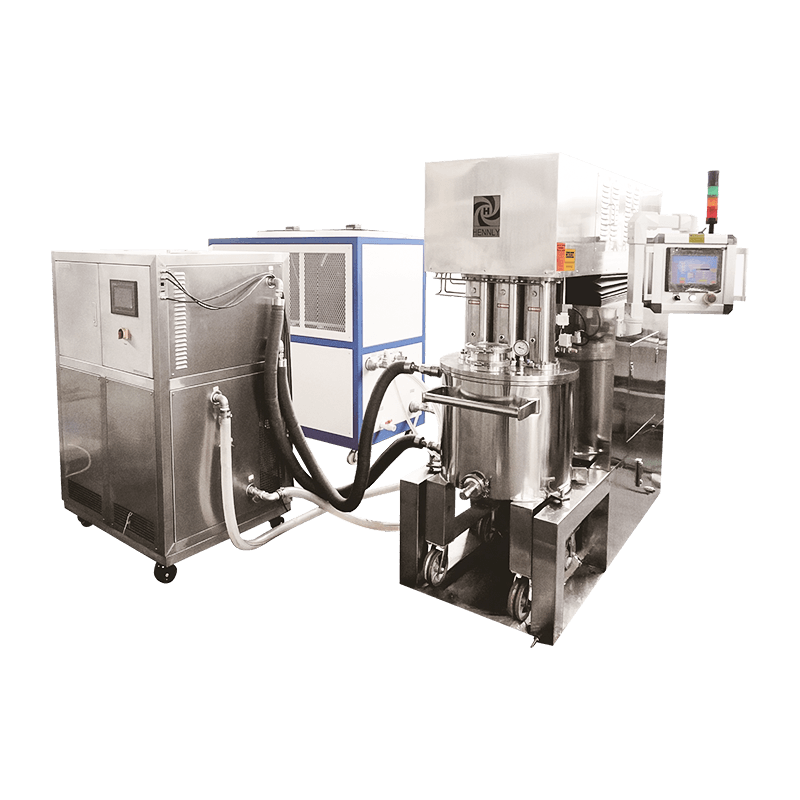

Precise control

The equipment is equipped with an intelligent control system, and users can easily adjust processing parameters such as speed, temperature and time to ensure consistency and stability of each batch of products.

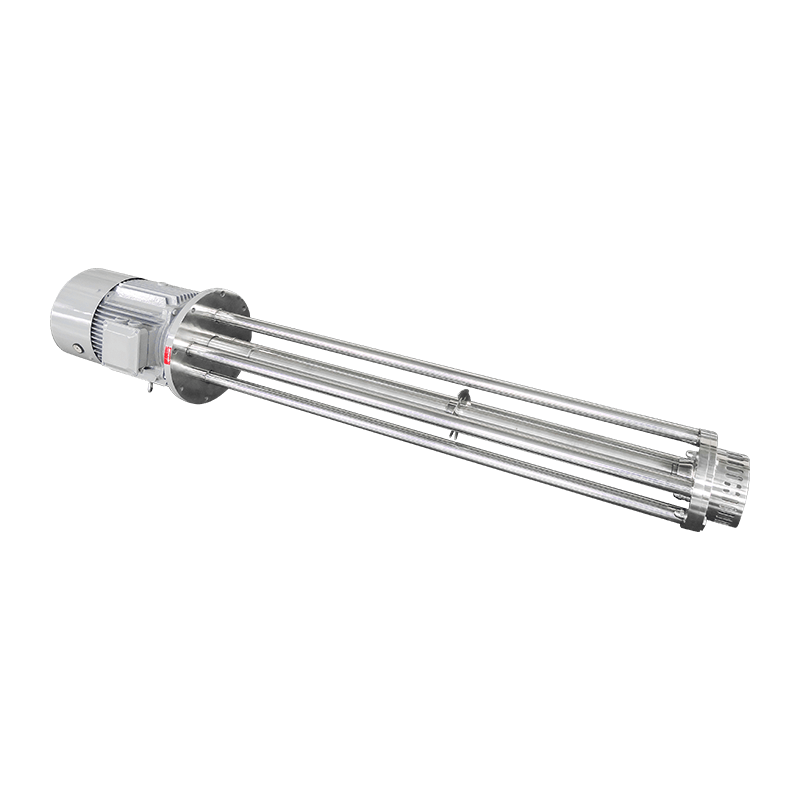

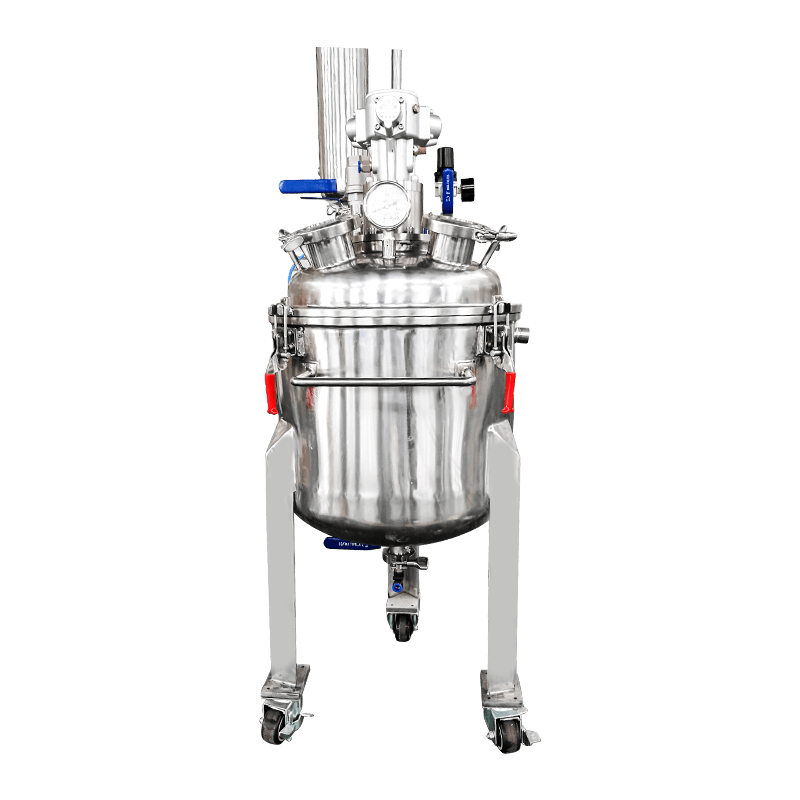

Wide applicability

Super gap emulsifiers are suitable for a variety of materials, including liquids, pastes and suspended substances, and can meet the emulsification needs of different products.

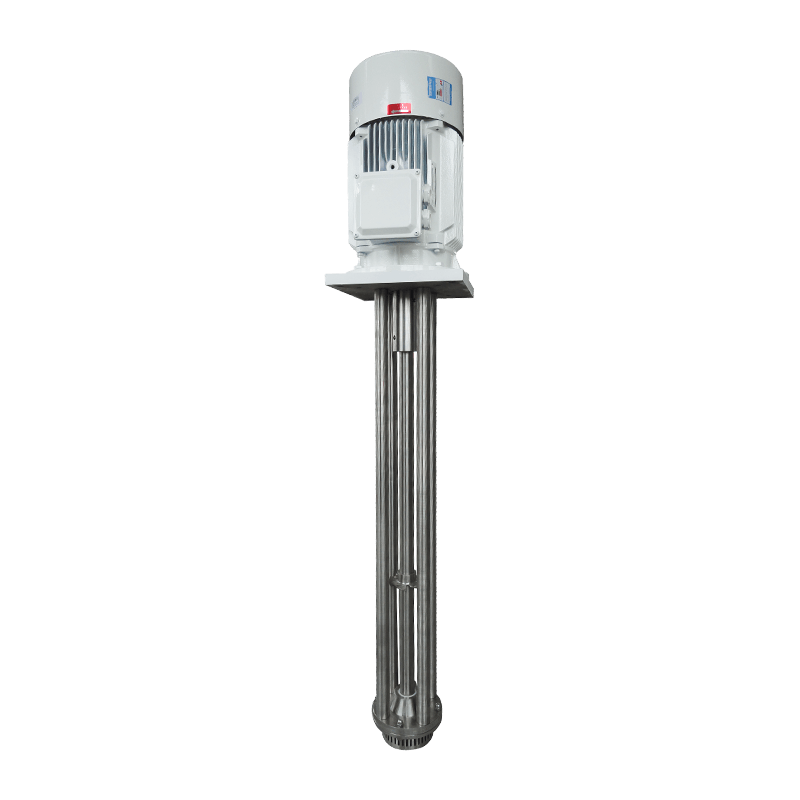

Easy to clean and maintain

The design meets hygiene standards, and the disassembly and cleaning of the equipment is very easy, providing convenience for quick product replacement and shortening cleaning time.

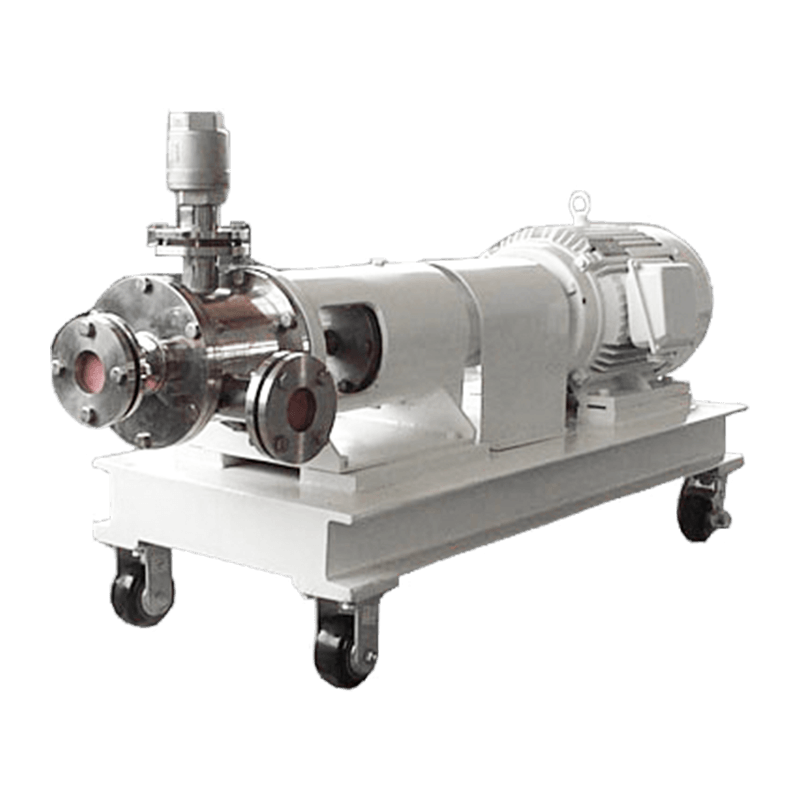

Energy-saving and environmental protection

Our emulsifiers adopt energy-saving technology to reduce energy consumption and reduce production costs, while meeting environmental protection requirements and creating greater economic benefits for enterprises.

Application areas

Food industry: used to make condiments, sauces, dairy products, etc. to ensure the uniformity and taste of the product.

Cosmetics industry: suitable for the production of lotions, face creams and skin care products to meet the high-end market's demand for product quality.

Pharmaceutical industry: used for emulsification and dispersion of drugs, ensuring the even distribution of active ingredients of drugs and improving drug efficacy.

Chemical industry: It is suitable for mixing and emulsification of various chemical raw materials to improve production efficiency and product quality.