Core Mechanical Dynamics: Differences Between Planetary and Spiral Motion Before diving into which mixer is superior, we must analyze their underlying mechanica...

READ MORECustom Industrial High Shear Mixer Manufacturers

-

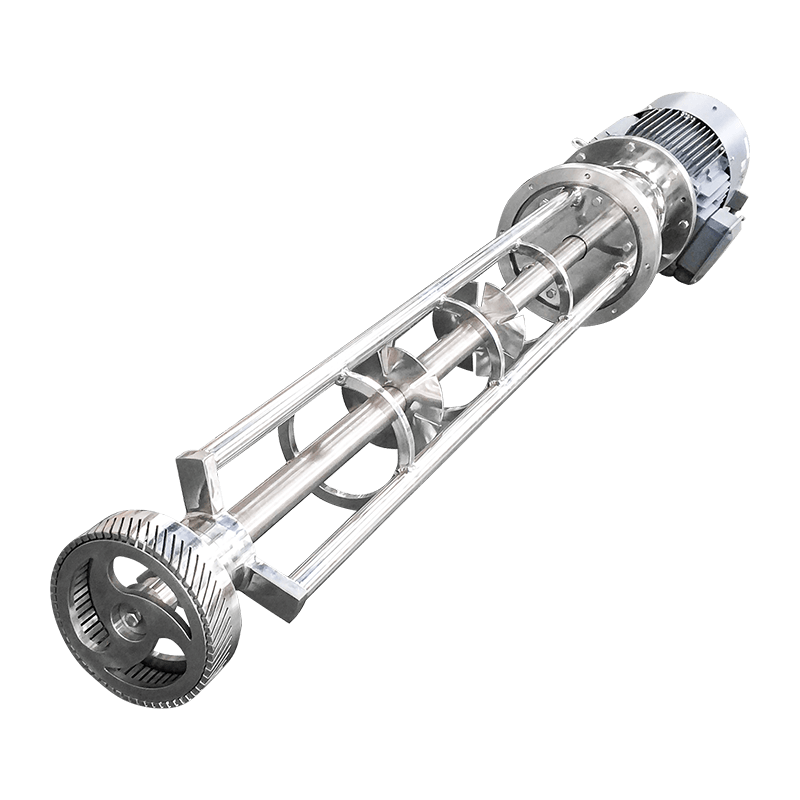

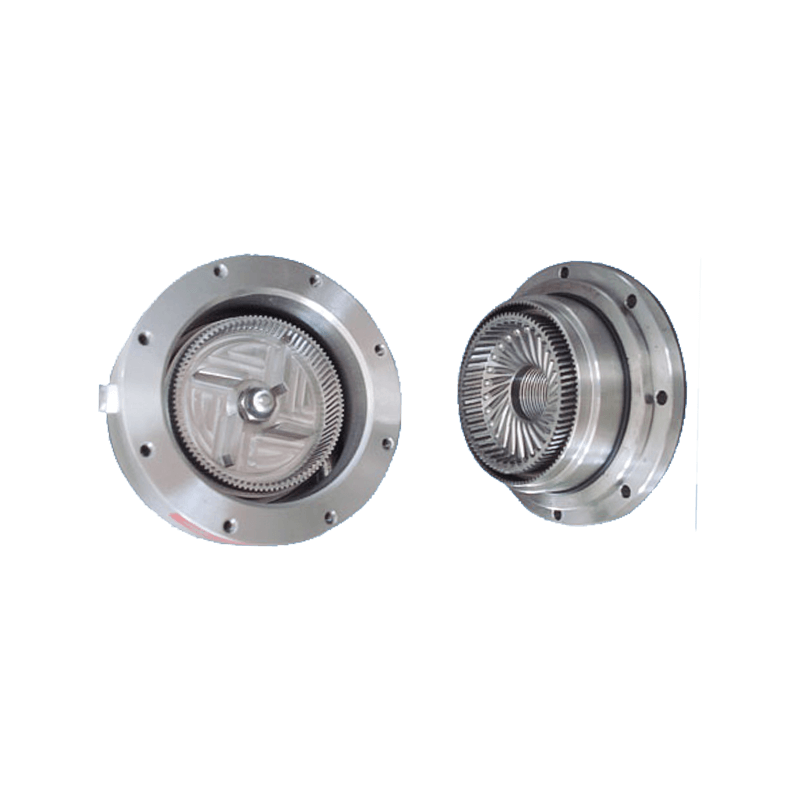

Muli-Stage Type of Mixer

When the material is sucked into the rotor area from the axial position, the mat...

-

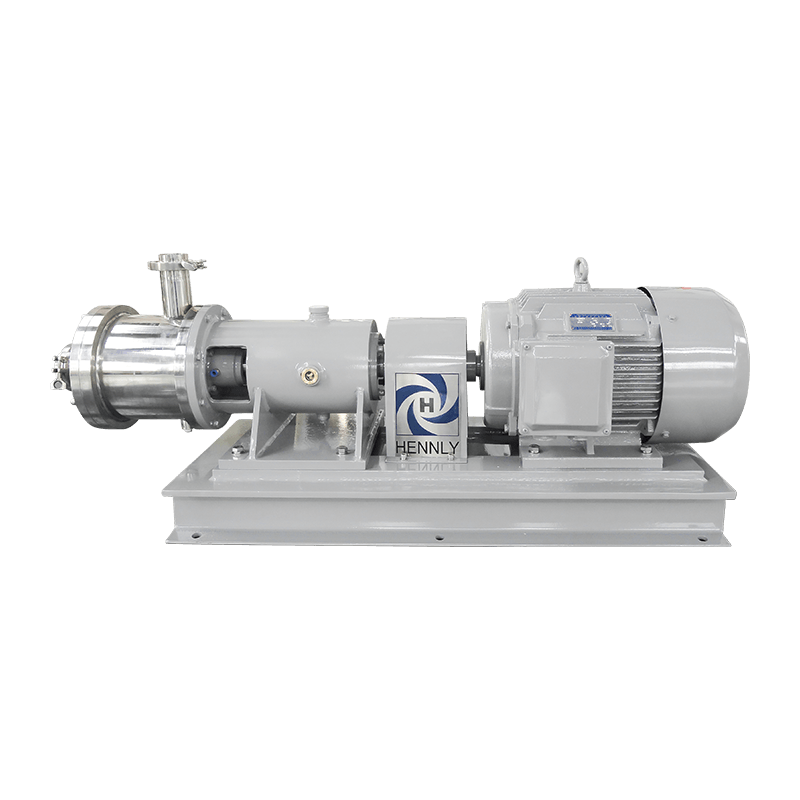

Siphon Type of Mixer

The siphon mixer creates a vacuum through the high-speed rotation of a special r...

-

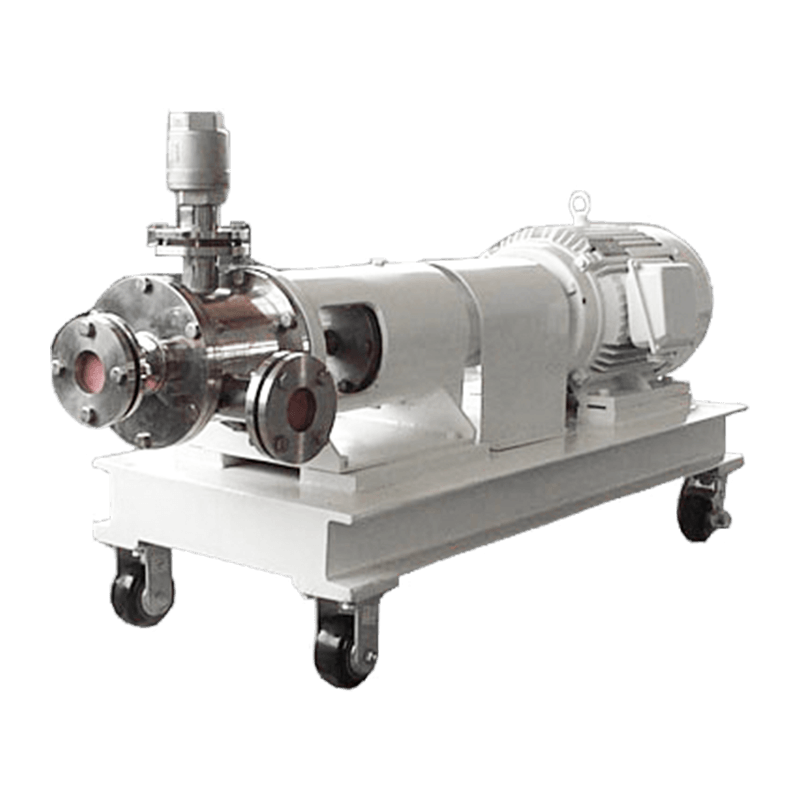

Grinder Pumps

The advantages of grinding pumps include high linear velocity small and adjustab...

With the rapid advancement of high technology, new products and processes place higher demands on equipment. In response.

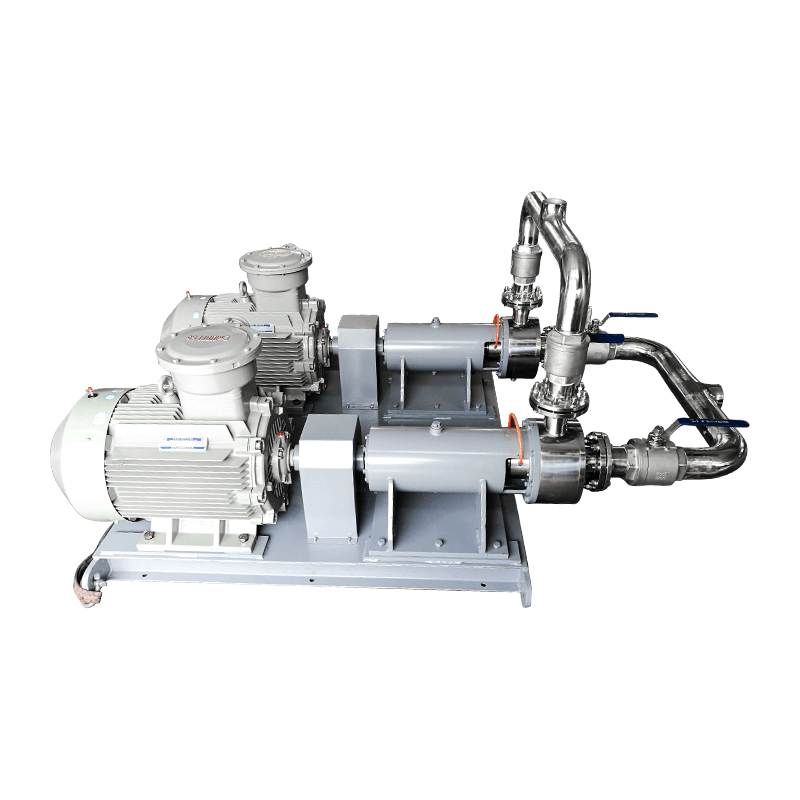

Nantong Hennly has introduced advanced foreign technology to develop various new types of high-shear emulsifiers. The key technology of the high-shear mixer lies in the rotor and stator. The gap and configuration of the rotor and stator directly affect the efficiency and effectiveness of emulsification. As more customers apply high-shear mixers to high-viscosity products, the traditional rotor and stator structures no longer meet these demands. Hennly an early adopter of this application, has designed a variety of emulsifying head structures and gained extensive experience in this field.

One standout feature of Hennly's high-shear mixers is their modular design. While maintaining the main structure, different emulsifying heads can be easily swapped to achieve varying results, thereby meeting diverse operational needs.

About HENNLY

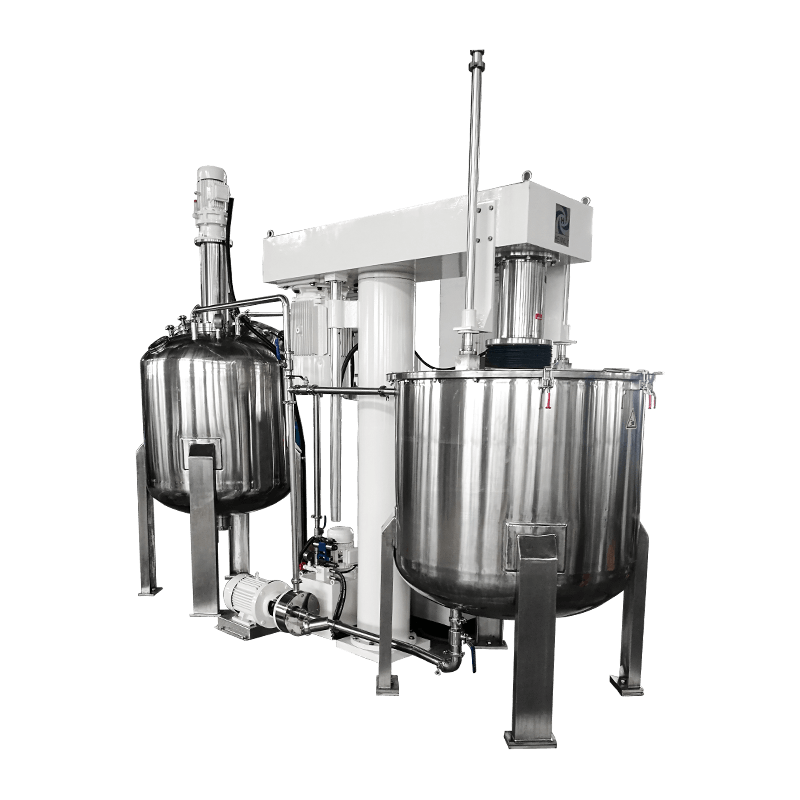

NanTong Hennly Machinery Equipment Co., Ltd. is China High Shear Mixer Manufacturers and Custom High Shear Mixer Factory that combines industry and trade, focusing on the research, development and production of excellent hybrid equipment. We have advanced processing equipment and an excellent team that has served the mixer equipment industry for many years. Our employees have superior expertise, extensive application experience and the ability to provide customers with a full range of process services from equipment selection to production. Based on high-quality and high-end markets, we mainly export to countries such as the United States, Germany, Japan, South Korea, Malaysia, Singapore, Vietnam, Indonesia and Egypt. The areas of cooperation with clients include pharmaceuticals, adhesives, thermal conductivity and heat dissipation, slurry, solder paste, batteries, polymer materials, food, and chemical industries.

- Wide range of applications

- 15 years of precipitation of technical design

- Non-standard customization (it can be customized according to customer needs)

- Direct docking service of factory

-

-

In the dual pursuit of extreme product quality and energy reduction, the cosmetic and pharmaceutical industries are undergoing a core process revolution. For a ...

READ MORE -

In precision chemical processing, pharmaceutical synthesis, and battery material production, Reaction Kinetics determines the ultimate yield and energy efficien...

READ MORE -

In the field of high-performance material preparation, the vacuum retention capability of an Industrial Double Planetary Mixer is a core indicator for ensuring ...

READ MORE

What are the safety protection measures for industrial high shear mixers?

In modern industrial production environments, equipment safety is a key factor in ensuring production efficiency and employee protection. NanTong Hennly Machinery is well aware of this, so it has taken a series of comprehensive safety protection measures in the design and operation of its industrial high shear mixers.

Safety protection at the design level

Protective covers and emergency stop devices

NanTong Hennly Machinery has installed sturdy protective covers on key parts of the industrial high shear mixer. This design effectively prevents operators from being injured by accidental contact or accidental involvement in rotating parts. In addition, the equipment is also equipped with a conspicuous emergency stop device to ensure that in the event of an emergency, the operator can quickly press the stop button and immediately cut off the power supply to maximize personal safety.

Overload protection device

In order to prevent overload problems caused by excessive materials or motor failure, NanTong Hennly Machinery's equipment is equipped with advanced overload protection devices. When the motor load exceeds the set threshold, the protection device will automatically cut off the power supply to avoid equipment damage and potential safety hazards. This design not only improves the reliability of the equipment, but also provides additional safety for operators.

Safety interlock system

NanTong Hennly Machinery is equipped with safety interlock devices at key operating parts of the equipment, such as door opening and feeding port. This system ensures that the equipment can only be started and operated when these parts are in a safe state. If these parts are opened or in an unsafe state, the equipment will automatically stop operating, thus effectively preventing accidents.

Safety protection during operation

Operation training and guidance

NanTong Hennly Machinery is well aware of the importance of the operator's professional skills to the safe operation of the equipment. Therefore, the company provides each customer with detailed operation training, covering equipment structure, performance, operation process and safety precautions. In addition, NanTong Hennly also provides operation manuals and safety guides to ensure that operators can refer to relevant information at any time to enhance safety awareness.

Personal protective equipment

When operating an industrial high-speed shear mixer, the operator must wear standard personal protective equipment, including safety helmets, protective glasses, protective clothing and protective gloves. NanTong Hennly Machinery provides a detailed list of personal protective equipment when the equipment is delivered, and recommends that customers regularly check and replace these equipment to ensure their effectiveness and reliability, thereby protecting the safety of operators.

Regular maintenance and inspection

In order to ensure the long-term stable operation of the equipment, NanTong Hennly Machinery recommends that customers perform regular equipment maintenance and inspection. These maintenance tasks include equipment cleaning, electrical connection inspection, key component lubrication and fastener loosening inspection. The company also provides customers with professional maintenance guidance and technical support to ensure that the equipment is always in the best working condition.

What are the precautions during the actual operation of industrial high shear mixer?

In modern industry, industrial high-speed shear mixers are widely used in chemical, food, pharmaceutical and other fields as an efficient mixing equipment. In order to ensure the safe and efficient operation of the equipment, operators need to make full preparations and standardized operations.

Preparation before operation

Personnel training

Before operating the industrial high-speed shear mixer, the operator must receive systematic training. This training includes the structure, performance, operation process and safety precautions of the equipment. NanTong Hennly Machinery provides each customer with a detailed operation manual and safety guide, and arranges professional technicians for on-site guidance to ensure that the operator can master the equipment's use skills and reduce operating risks.

Equipment inspection

Before formal operation, the operator should conduct a comprehensive inspection of the industrial high-speed shear mixer. This includes key components such as electrical systems, transmission systems, lubrication systems and safety protection devices. Ensure that the equipment is in good condition and free of abnormalities. In addition, operators need to check whether there are foreign objects in the operating parts of the equipment to prevent potential accidents.

Raw material preparation

According to production requirements, operators need to prepare the required raw materials and additives in advance, and classify and configure them reasonably. Ensure that the quality of raw materials meets production standards to avoid equipment failure or substandard product quality caused by raw material problems.

Precautions during operation

Safety protection

When operating an industrial high-speed shear mixer, operators must wear appropriate safety protection equipment, such as safety helmets, protective glasses, protective clothing and gloves. At the same time, ensure that the protective devices of the equipment are intact to prevent accidental injuries.

Operating specifications

Operators should operate strictly in accordance with the operating procedures of the equipment, and any violations are strictly prohibited. Before starting the equipment, it is necessary to confirm the correctness of the settings of various parameters, including mixing time and mixing speed. During the mixing process, check the operating status of the equipment regularly. If any abnormality is found, stop the machine immediately for inspection to ensure that the fault is eliminated before continuing the operation.

Raw material delivery

When delivering raw materials, operators should strictly follow the formula ratio to add them to avoid over- or under-delivery. At the same time, pay attention to the order and method of raw material delivery to ensure that they can be evenly mixed. During the delivery process, it is strictly forbidden to mix foreign matter or hard objects into the equipment to avoid damage to the equipment or affect the quality of the final product.

Equipment monitoring

During the entire operation process, operators need to pay close attention to the operating status of the equipment, including indicators such as motor temperature, lubrication and noise. Once any abnormality is found, the machine should be stopped for inspection immediately to avoid equipment damage or safety accidents.

Finishing work after operation

Equipment cleaning

After the operation, the operator should clean the industrial high-speed shear mixer in time to remove the residue and dirt inside the equipment. This not only helps to keep the equipment clean and tidy, but also increases the service life of the equipment.

Equipment maintenance

Regular maintenance and maintenance of the industrial high-speed shear mixer is an important part of ensuring the normal operation of the equipment. This includes lubrication, tightening screws and replacing wearing parts to ensure the stability of the equipment and extend its service life.

Recording and Feedback

The operator should record the process and results of each operation in detail, including the amount of raw materials put in, mixing time and mixing speed, etc. At the same time, timely feedback to the technical staff on the operation status of the equipment and existing problems so as to make necessary processing and improvements.

Are you interested in our products?

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.