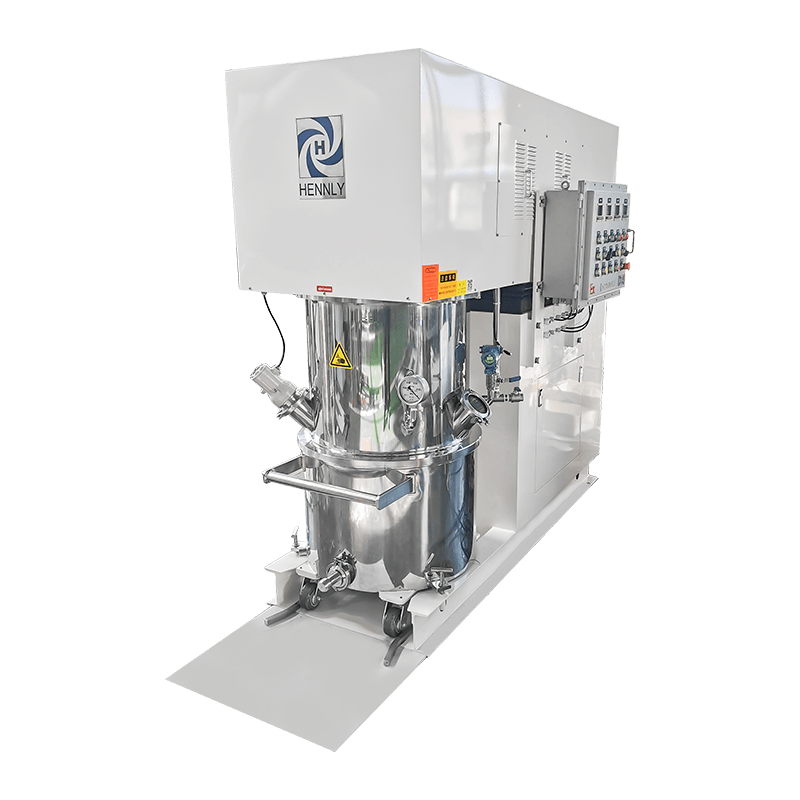

Standard Mixer

Cat:Multi-Shaft Mixer

The standard mixer is suitable for most products with material viscosities under 500,000 CPs. This machine emphasizes material crushing and emulsifica...

See DetailsTriple Planetary Mixer is widely used in industrial production, especially in the chemical, pharmaceutical, food and other industries. Due to its excellent performance in mixing high-viscosity and corrosive materials, the durability and corrosion resistance of the equipment are particularly important. Long-term contact with corrosive substances such as chemicals, inks, and coatings, if the surface of the equipment is not effectively protected against corrosion, it is easy to cause corrosion and wear of the equipment, and even affect the quality of the product. Therefore, for the anti-corrosion treatment measures of Triple Planetary Mixer, a systematic protection method must be adopted to ensure the long-term stable operation of the equipment.

1. Select corrosion-resistant materials

When designing and manufacturing Triple Planetary Mixer, material selection is crucial. The main components of the equipment, such as agitators, containers, bearing seats, etc., usually need to be made of corrosion-resistant materials. Common corrosion-resistant materials include stainless steel (such as 304, 316L stainless steel), alloy steel, and some special corrosion-resistant synthetic materials. Stainless steel is the most commonly used material. It not only has good antioxidant properties, but also can effectively prevent chemical corrosion. In some special cases, coatings or surface treatment technologies may also be used to further improve the corrosion resistance of the equipment.

2. Surface coating protection

For some stainless steel or other metal parts, surface coating treatment is an effective way to improve the corrosion resistance. Common coating protection methods include spraying epoxy resin, polyurethane coating and high molecular polymer coating. These coatings can effectively isolate the metal surface from direct contact with external corrosive substances and prevent corrosion reactions caused by long-term contact with chemicals, acidic and alkaline substances or solvents.

The thickness and uniformity of the spray coating have a direct impact on the anti-corrosion effect. Therefore, during the coating process, the coating thickness, construction environment and curing time must be strictly controlled to ensure the stability and durability of the coating. For parts that need to be cleaned frequently, the surface coating should have good wear resistance.

3. Anodizing treatment

Anodizing treatment is a commonly used anti-corrosion method for aluminum alloys and aluminum parts. Through electrolytic treatment, a dense oxide film is generated on the aluminum surface, which can effectively prevent the aluminum surface from contacting with external corrosive media. For some special requirements of Triple Planetary Mixer, if some parts of the equipment need to be affected by acidic or alkaline materials, anodizing technology can be used to enhance its corrosion resistance.

4. Metal surface spraying and hot-dip galvanizing

For some more complex parts, hot-dip galvanizing is an effective anti-corrosion treatment technology. By immersing metal parts in molten metal (such as zinc, aluminum), a solid protective layer is formed. Especially in large planetary three-shaft mixers, exposed metal parts are easily corroded by the external environment. Hot-dip galvanizing can significantly improve the corrosion resistance of the equipment and extend its service life.

In addition, some parts such as stirring paddles and stirring shafts often use spraying technology to spray a protective film on the surface of the equipment using anti-corrosion coatings. There are many types of spray coatings. You can choose suitable coatings according to the characteristics of the materials used, such as epoxy resin coatings, polyurethane coatings, etc. These coatings not only have anti-corrosion properties, but also have the characteristics of wear resistance and high temperature resistance.

5. Anti-corrosion design of sealing system

The sealing system in Triple Planetary Mixer is usually an important part of anti-corrosion treatment. The sealing system is mainly used to prevent material leakage and protect internal bearings, gears and other precision parts from corrosion. Sealing parts such as sealing rings, O-rings, bearing seals, etc. must be made of materials with corrosion resistance and wear resistance. Common materials include fluororubber, silicone, etc.

When designing seals, a lubrication system is usually added, which not only reduces friction and wear, but also improves the corrosion resistance of the sealing system. The selection of sealing parts and lubricants needs to be based on the specific working environment to avoid equipment performance degradation or corrosion due to unsuitable materials or lubricants.

6. Regular inspection and maintenance of anti-corrosion coatings

Even if the surface of the equipment is treated with anti-corrosion coatings, long-term use may still cause the coating to peel off or wear. In order to ensure the anti-corrosion effect, regular inspection and maintenance are essential. Operators need to regularly check the integrity of the coating on the surface of the equipment, promptly identify damaged or detached parts of the coating, and re-coat or re-coat. Especially in the case of high-frequency use, the maintenance of the coating should be more frequent.

Experienced employees & experts are Always At Your Service to provide you with satisfactory products & professional instruction on technical problem solutions.